Levi’s Cloud Migration and Transformation: Modernizing a Century-Old Icon for the Digital Age

In 2011, Levi Strauss & Co. was stagnating with flat sales around $4.2 billion and a customer base averaging 47-year-old men.

In 2011, Levi Strauss & Co. was stagnating with flat sales around $4.2 billion and a customer base averaging 47-year-old men.

New CEO Chip Bergh, a lifelong fan, launched a turnaround built on four pillars: strengthening core products, expanding women’s lines and emerging markets, growing e-commerce, and embracing data and technology.

The breakthrough came with Levi’s Future-Led Execution (FLX), an AI-powered operating system that reinvented how jeans are made.

AI analyzes millions of images to catalog every whisker, rip, and fade, predicts trending finishes, and optimizes production on demand. Customers design custom pairs in-store on iPads or online. Today, 15–20% of Levi’s seasonal assortment is laser-produced, slashing waste, inventory risk, and environmental impact.

What began as a quest to clean up a polluting process has transformed Levi’s into a software-driven company. By digitizing the entire jeans-making workflow and harnessing AI for trend forecasting and sustainability, Levi’s has not only revived its iconic brand but redefined what a 170-year-old apparel maker can be in the digital age.

|

An Introduction to the Case Study of Levi Strauss & Co.’s Cloud and AI Transformation

In the annals of American business history, few names carry the weight of Levi Strauss & Co. (LS&Co.). Founded in 1853 during the chaos of the California Gold Rush, the company built its reputation on durability—providing riveted denim for miners who needed clothes that wouldn’t tear under pressure.

Today, nearly 175 years later, the company faces a different kind of pressure: the relentless volatility of the digital economy. In response, Levi’s has executed one of the retail sector’s most comprehensive digital transformations, proving that a heritage brand can pivot with the agility of a tech startup.

This article introduces a detailed research report on Levi’s journey from a wholesale-reliant legacy manufacturer to a direct-to-consumer (DTC) digital powerhouse. It explores how the company rewired its DNA—moving from “data rich, insights poor” to a predictive, AI-driven enterprise that is defining the future of “Agentic Commerce.”

The Strategic Pivot: Overcoming Wholesale Blindness

For most of its history, Levi’s operated as a wholesaler. They made jeans and shipped them to department stores, effectively losing sight of the customer at the loading dock. This model created a disconnect; the company didn’t know who was buying their jeans, when they were buying them, or why they were returning them.

The research highlights a critical strategic pivot initiated under leadership that recognized the “Retail Apocalypse” not as a death knell, but as a call to action. The goal became “DTC First”—owning the relationship with the consumer. By the third quarter of 2025, this strategy resulted in DTC channels accounting for 46% of total net revenues, with e-commerce growing 16% organically.

To achieve this, Levi’s had to dismantle its siloed legacy infrastructure and build a single, global “source of truth.”

The Backbone: Cloud Migration and Project SOLAR

The transformation began with the “unsexy” but vital work of infrastructure modernization. The research details Project SOLAR, a massive initiative to migrate the company’s fractured Enterprise Resource Planning (ERP) landscape to a unified SAP S/4HANA instance in the cloud.

Previously, Levi’s operated with regionally distinct SAP instances—one for the Americas, one for Europe, and one for Asia—making real-time global inventory visibility impossible. By consolidating these into a single global platform, enabled by partners like Syniti for complex data migration, Levi’s created the digital backbone necessary for modern retail.[3] This move to the cloud was not just about storage; it was about agility, allowing the company to upgrade systems without downtime and scale operations dynamically.

Simultaneously, Levi’s adopted a multi-cloud strategy, leveraging Google Cloud Platform (GCP) for consumer data analytics and Microsoft Azure for enterprise workloads and AI agents. This hybrid approach allowed them to exploit the specific strengths of each hyperscaler, avoiding vendor lock-in while maximizing capability.

Digitizing the Physical: Lasers and The Internet of Things

Perhaps the most visually arresting aspect of Levi’s transformation covered in the report is Project F.L.X. (Future-Led Execution). Traditionally, creating the “worn” look on denim involved manual labor and hazardous chemicals. It was slow, inconsistent, and environmentally taxing.

Project F.L.X. digitized this process. Designers now “paint” finishes on an iPad, and high-speed lasers burn those designs onto denim in 90 seconds. This innovation allowed Levi’s to embrace a supply chain strategy of “postponement.” Instead of finishing jeans months in advance, they can hold raw inventory and laser it based on real-time demand signals, reducing lead times from months to weeks. This not only aligns with the company’s sustainability goals—eliminating thousands of chemical formulations—but also drastically reduces inventory risk.[9]

Complementing this is the deployment of RFID (Radio Frequency Identification) technology. Partnering with Intel and Avery Dennison, Levi’s tagged items across its fleet, achieving near 100% inventory accuracy.[10] This “Internet of Things” layer allows stores to function as mini-fulfillment centers, enabling accurate “Ship from Store” capabilities that are essential for a profitable DTC model.

The Brain: AI, Machine Learning, and “The Superagent”

With cloud infrastructure and digital manufacturing in place, Levi’s turned to Artificial Intelligence to drive decision-making. The report analyzes how the company solved its “data rich, insights poor” paradox.

- Precision Forecasting: leveraging cloud-based data lakes, Levi’s replaced spreadsheet intuition with machine learning models that analyze variables ranging from weather patterns to competitor pricing. The result was a double-digit percentage improvement in forecast accuracy, significantly reducing markdowns and waste.[12, 13]

- The BOOST Engine: The report highlights the “BOOST” (Business Optimization Of Shipping and Transport) engine, which uses AI to determine the most profitable fulfillment node for every online order, balancing speed against shipping costs and markdown risks.[14]

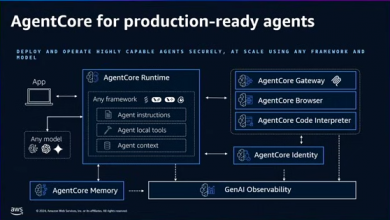

- Agentic AI: Looking to the future (2025-2026), the research details the partnership with Microsoft to deploy an “orchestrator agent” or “Superagent” within Microsoft Teams.[15, 16] This AI acts as a conversational interface for employees, routing complex queries to specialized sub-agents in HR, IT, or Supply Chain, effectively automating the bureaucracy of a large enterprise.

- Styling the Customer: On the consumer side, the “Outfitting” tool and “Stitch” assistant for store associates use deep learning to recommend complete looks rather than just individual items, creating a hyper-personalized shopping experience.[17, 18]

Culture as Code: The Machine Learning Bootcamp

Technology is useless without a workforce capable of wielding it. A standout finding in the report is Levi’s commitment to internal upskilling. Rather than relying solely on Silicon Valley hires, the company launched an industry-first Machine Learning Bootcamp.[19]

This program took employees from diverse backgrounds—store managers, designers, finance analysts—and trained them in Python and data science.[20] This strategy created a cadre of “domain experts who code,” bridging the gap between technical capability and business intuition. It fostered a culture where innovation happens at the edge, driven by the people who know the product best.

Conclusion: A Blueprint for Modernization

The case study of Levi Strauss & Co. serves as a definitive blueprint for legacy enterprise transformation. It illustrates that modernization is not a single project but a convergence of strategies: Cloud to unify data, AI to predict demand, IoT to track assets, and Digital Manufacturing to execute with speed.

By 2024, initiatives like Project Fuel had generated over $100 million in cost savings, capital that was reinvested into the technology stack. As the company moves toward an era of “Agentic Commerce,” it stands as a testament to the idea that even the oldest brands can lead the newest revolutions. Levi’s didn’t just survive the transition to digital; they tailored it to fit them perfectly.

Download the full

Download the full